Sugar Industry Services

I-Tech Services includes a menu that cuts across the needs of the sugar industries. In more than 10 years, we suggest individual strategies providing optimization of processes, dependability of outcomes, and their maximum quality for any sphere of work in sugar plant. We are indeed fully involved in all aspects related to sugar company maintenance, plant construction, right up to operations and improvement, making us the preferred supplier to the sugar manufacturers and sugar company service providers.

Our Services

EPC

Expertise in Engineering, Procurement, and Construction for sugar plants and distilleries

BMRE

Solutions for Balancing, Modernization, Rehabilitation, and Expansion of sugar plants.

Plant Maintenance

Tailored annual turnarounds for optimal sugar plant performance.

Fabrication

Fabrication of essential equipment for the sugar and distillery sectors.

Refurbishment

Refurbishment services restore and upgrade industrial equipment, enhancing performance and extending its lifespan.

Erection

Precise installation of industrial plants and machinery.

Comprehensive Solutions for the Sugar Industry

EPC: Engineering Procurement & Construction

EPC for Sugar Plants

I-Tech services mainly deal in engineering procurement and construction especially in operation of sugar plants and distilleries; spanning over a decade of sugar industry experience. I-Tech Services provide Engineering, Procurement and Construction (EPC solutions) specifically designed for the Sugar Sector. We are conversant with design, construction, testing, installation and commissioning of a variety of equipment. Since the costs are a critical factor, it is our business interest to deliver your sugar plants in the shortest time possible and meet all the industry benchmarks.

Key benefits of our EPC services include:

End-to-end project management: We manage your project from slightly at the drawing table to the Physical construction phase.

Cost-effective solutions: This way, we keep the costs down by having efficiency in our processes and sensible sourcing.

Timely delivery: We maintain proper schedule so as to deliver your project within the required time frame.

Operational efficiency: We ensure the best outcome of plant designs and construction processes.

Choose I-Tech Services as your service provider to help you construct excellent sugar plants. Get in touch with us now to know more about a project you want to execute.

BMRE: Balancing, Modernization, Rehabilitation & Expansion

Balancing: Making sure that methods utilised for a specific activity create the highest productivity.

Modernization: Replacing old technology with the new one that is in the market.

Rehabilitation: Returning often heavily used or worn out equipment to its original state.

Expansion: The expansion of existing facilities and capacity for new plant to meet a growing marketplace.

By implementing BMRE strategies, you can:

Improve plant efficiency: Minimizing on time wastage while at the same time; boost productivity on production.

Reduce energy consumption: Reduced cost of operations and x decrease y environmental effects.

Extend equipment lifespan: Increase the life cycle of your machinery and decrease your maintenance costs.

Increase capacity: Cater for increasing market needs of sugar company and add value to the operations of your business.

Plant Maintenance

Maintenance of Sugar Plants and its Various Systems

I-Tech Services provides targeted plant maintenance services to ensure the effective and optimum performance of your sugar plant.

Our services include:

Routine maintenance: Such mistakes like of equipment are detected through inspection, cleaning, and lubrication.

Troubleshooting: Quick identification of faults; this should be followed by their repairs so that the machines do not spend a lot of time out of order.

Annual turnarounds: Preventable maintenance and refurbishment that require machines to be out of operation for a long time.

By prioritizing plant maintenance, you can:

Maximize uptime: Minimize or avoid any unwanted downtime thus meeting production schedules.

Optimize performance: The mechanical equipment of your business should be optimally performing.

Extend equipment lifespan: Increase the durability of your equipment and decrease your outfit costs spent on new equipment.

Improve safety: Safety issues in a workplace should also be established and analyzed for safety risks.

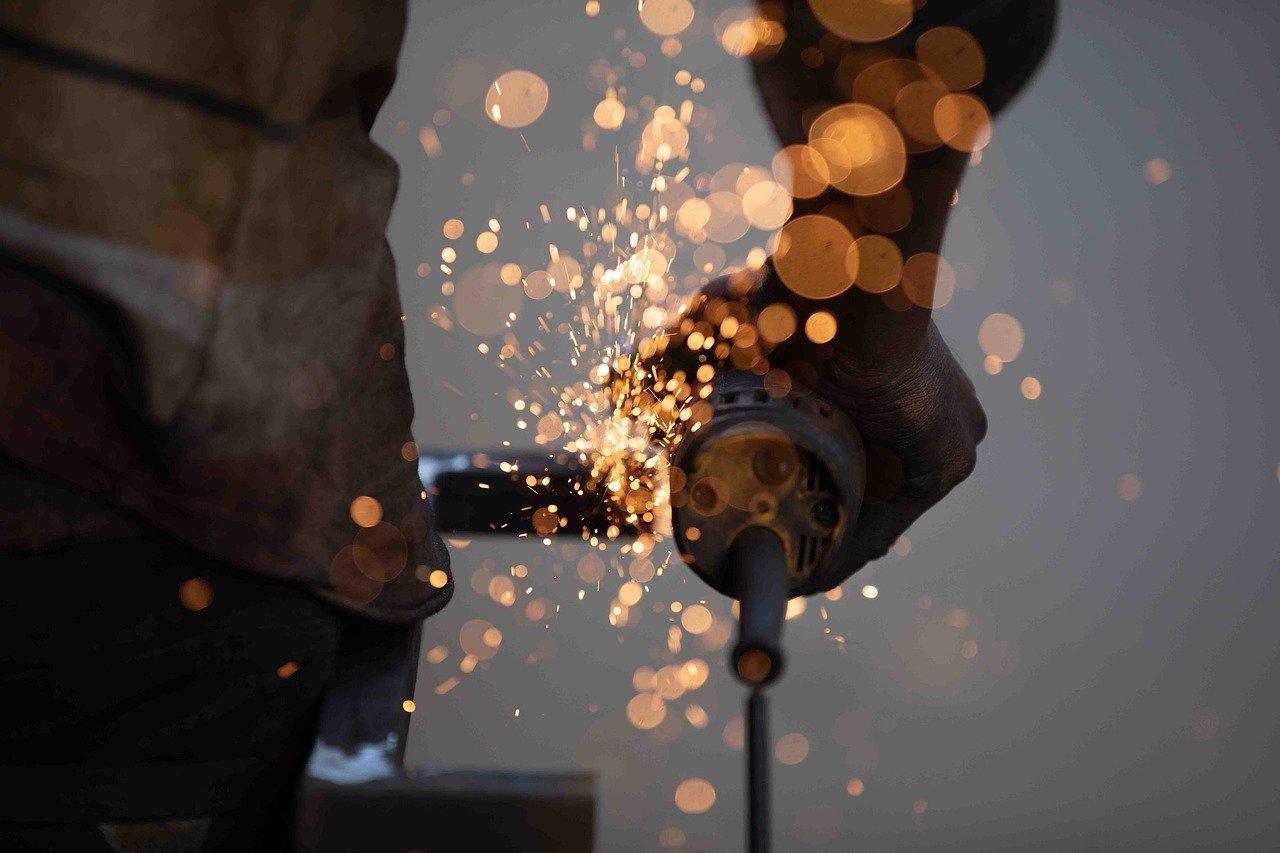

Fabrication

Fabrication for Sugar Plants

I-Tech Services offer the equipment manufacturing services because it has an in-house fabrication crew to supply quality equipment and components that are ideal for the sugar company/ industry.

Our capabilities include:

Large structural elements: Manufacturing of the principal structures and bearing parts of sugar factories.

Specialized parts: Producing metallic work products like gears, shafts or valves with maximum accuracy.

Custom designs: How fabrication services can be adapted to suit a specific project.

By choosing our fabrication services, you benefit from:

Quality assurance: Inspecting if all the components in the system conform to the standard that is current in the market.

Timely delivery: Avoiding activities such as delay of activities or timeframe such as delay in time schedules of projects.

Cost-effective solutions: Recently, there are some strategies identified that could be used to optimize fabrication process, and in particular to minimize fabrication costs further.

Customization: Having precisely received an order that you wanted to request, which corresponds to your individual wishes.

Erection

Precise Erection Services for Sugar Plants

I-Tech Services is involved in the elevation of industrial plants and equipment such as sugar mills.

Our experienced team ensures the productivity:

Heavy machinery: Stepped and operated with utmost delicacy of touch.

Structural components: Are accurately assembled and integrated and checked.

All systems: Of these sub-processes, some are aligned and integrated for the best performance.

Safety precautions are strictly observed and we imply standard procedures to minimize disruption and delays in construction through efficient erection.

Our goal is to deliver a fully functional plant that meets your exact specifications.

Steam Turbines

Steam Turbine Services for Sugar Plants

I-Tech Services offers comprehensive steam turbine services to meet the energy needs of the sugar industry.

Our expertise includes:

- Installation and Commissioning: To make certain that turbines are set up and functional properly.

- Maintenance and Upgrades: Maintaining the conditions of turbines and enhancing the operations of the turbines.

- Efficiency Optimization: Optimization of energy production and minimization on its wastage.

- Long-Term Reliability: To make turbines function stably and perpetually.

By choosing ITS Group, you can:

Improve energy efficiency: Increase power-steam conversion efficiency.

- Reduce costs: Reduce energy costs on the one hand while down time is drastically minimized on the other hand.

- Enhance sustainability: Minimise your plant’s environmental impact.

- Ensure reliability: Maintain your performance of your turbines.

- Enhance sustainability: Optimize your plant’s environmental footprint.

- Ensure reliability: Keep your turbines operating at peak performance.

Steam Boilers

Steam Boiler Services for Sugar Plants

I-Tech offers complete solutions in steam boiler offerings for this particular sector. Key competencies of our services range from handling high-pressure and mid to low pressure steam and hot water boilers used in manufacturing and energy applications.

Key services include:

- Installation and Commissioning: Precise installation of boilers for optimal performance.

- Maintenance and Repairs: Regular inspections, cleaning, and repairs to prevent breakdowns.

- Efficiency Optimization: Enhancing boiler efficiency to reduce fuel consumption.

- Long-Term Reliability: Ensuring safe and reliable operation over time.

Benefits of our steam boiler services:

- Improved efficiency: Reduce fuel consumption and operational costs.

- Enhanced safety: Prevent breakdowns and ensure safe operation.

- Increased reliability: Minimize downtime and maintain continuous production.

- Extended lifespan: Prolong the life of your boiler equipment.

FFE: Falling Film Evaporator

Falling Film Evaporator (FFE) Services

I-Tech Services specialized in providing comprehensive services for Falling Film Evaporators (FFE), essential for efficient sugar juice concentration.

Our expertise includes:

- Installation and Commissioning: Ensuring FFEs are installed correctly and operate optimally.

- Maintenance and Repairs: Keeping FFEs clean and in good condition to prevent breakdowns.

- Efficiency Optimization: Enhancing evaporation rates and reducing energy consumption.

- Long-Term Reliability: Ensuring FFEs operate consistently and reliably.

Benefits of our FFE services:

- Improved efficiency: Increase evaporation rates and reduce energy consumption.

- Enhanced productivity: Maintain consistent production flow and reduce downtime.

- Lower costs: Minimize operational expenses and maximize sugar concentration.

- Increased reliability: Ensure your FFEs operate reliably over the long term.

Refurbishment and Modification

We firmly believe that our mission is to ensure that each piece of your industrial equipment meets your expectations and generates as much value as possible for sugar company. We provide full-service refurbishment and modification capabilities to revitalize your current equipment, improve its functionality, and retrofit them to meet present technological specifications.

Key Services:

Equipment Refurbishment: We are particularly interested in products that have faded, worn, or are of a considerably older model than people currently prefer. We refresh your machinery through thorough inspections, repairs, and replacement of faulty parts to make your machinery run as efficiently as before. Not only is it possible to increase efficiency, but it is also possible to save money on production through refurbishment instead of buying new equipment.

Modification and Upgrades: Your equipment may have to be modified based on the changes in technology and the needs of the sugar company industries. We provide more specialized modification in this respect of ITS Group – design with new technologies of the retrofitting equipment, improve certain capabilities and adapt to the optimum needs of specific applications. These upgrades allow you to maintain your machinery as modern, productive and safe as necessary.

Performance Optimization: However, our aim is to enable you get the best out of any equipment you have or might need in the future. What we want to stress is that we can optimize our productivity, minimize time wastage, and thereby decrease operating expenses by means of effective enhancements and developments. Currently, if you are narrowing your goal to increasing volume or decreasing your energy consumption, optimization solutions, allow us to help you reach your goal.

Client Testimonials

“The service provided by ITS Group was exceptional. Their expertise in EPC solutions significantly improved our project’s efficiency. Highly recommended!”

“Working with ITS Group was a great experience. Their timely delivery and quality of work in logistics services exceeded our expectations. We look forward to future collaborations!”

“ITS Group demonstrated professionalism and commitment throughout our engagement. Their plant maintenance services were thorough and effective, earning them a five-star rating!”